Mazda Rotary Parts are the lifeblood of Mazda. They have been making cars that use rotary engines since 1963, and they continue to do so today. Mazda has never made a car without these parts in it.

The last Mazda model with a rotary engine was the RX-8, which was discontinued in 2012. There are many reasons that Mazda still produces rotary engines. One is that they produce fewer emissions than other engine types when the car is running.

However, Mazda knows that they are still in the early stages of their rotary engine. Mazda will continue to produce these engines and will probably move to other engines in the future.

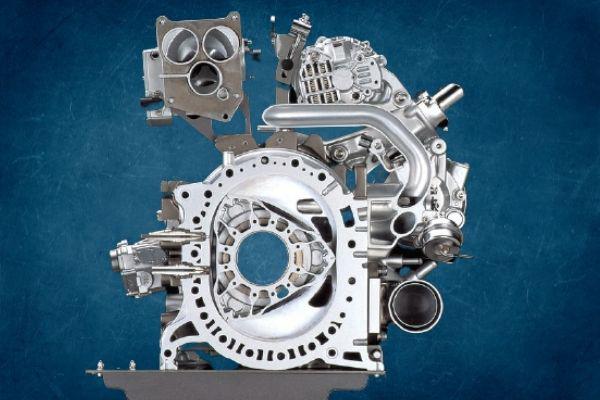

What is the Mazda rotary engine?

The Mazda rotary engine is a type of internal combustion engine that uses a rotary piston to pump air. This design provides many benefits including compact size, lightweight, and good fuel efficiency.

Because the Mazda rotary engine operates on the Otto cycle it can use a variety of fuels including gasoline and natural gas. The Mazda rotary engine is a type of internal combustion engine that uses a rotary piston to pump air.

This design provides many benefits including compact size, lightweight, and good fuel efficiency. Because the Mazda rotary engine operates on the Otto cycle it can use a variety of fuels including gasoline and natural gas.

How to identify a Mazda rotary engine?

Mazda is a Japanese automaker most well-known for its sporty and reliable cars. One of the most popular models they’ve produced is the RX-7, which sports a rotary engine.

Often, when people encounter a Mazda with this type of engine, they’re not sure what it is. These engines are often recognized for their unique sound and triangular shape that hangs off the top of the engine bay.

How does a Mazda rotary engine work?

Mazda’s rotary engines work on the Otto cycle – like a four-stroke engine. This means that every time the engine turns, the air and fuel mixture is compressed, ignited, and exploded. As the air is compressed, the spark plug ignites it, which causes the mixture to combust and creates energy.

As the mixture combusts, it expands and creates more pressure and heat. That pressure and heat are then transferred to the crankshaft, which is attached to the pistons.

The pistons push the crankshaft, causing the crankshaft to rotate. As the crankshaft rotates, the pistons move into the cylinders, compressing the air and fuel mixture again.

The cycle begins again and the piston repeats the cycle. All of this energy can be converted from rotational energy into usable power. The internal combustion engine is very efficient up to 95 percent and, while it uses fossil fuels, it is considered a clean source.

What are the benefits of a Mazda rotary engine?

- Mazda rotary engines have low levels of CO2, no tailpipe emissions, and are quiet.

- Mazda rotary engines are also easy to repair and maintain.

- Mazda rotary engines are also lightweight.

- Mazda rotary engines are also durable.

- Mazda rotary engines are also good for fuel-efficiency.

Do Mazda rotary engines are legendary for their performance?

Mazda Rotary engines are the most enigmatic and legendary among car enthusiasts. They were designed by Felix Wankel in 1963, and all of the components are entirely contained within a housing that is the same shape as the engine.

The technology behind the rotary engine that you need to know about?

In the Mazda Rotary engine, the crankshaft is replaced by a rotor, which looks like a spinning top. The rotary engine’s design is not new it has been around for over a century.

What’s new, however, is that today engineers are designing more efficient and reliable engines that can be mass-produced for less cost. Rotary engines are more efficient than conventional engines in terms of fuel consumption and emissions.

The rotary engine is also less noisy than conventional engines. It’s this quietness that made it ideal for automobiles.

Mazda’s first car to use the rotary engine was the 1967 Cosmo Sport 110S which had a 1171cc (0.9 liters) unit. Production of this type of engine stopped in 2012 because it has higher fuel consumption than traditional engines.

Mazda Rotary Parts

These are the following Mazda Rotary Parts:

Piston

The Piston is one of the most important parts of a rotary engine. The piston is inserted into a cylinder that has been created by an aluminum or copper liner.

The piston will ignite the air-gas mixture that is located between it and the lightweight metal liner which will cause combustion to occur.

In a rotary engine, a piston is used to compress the fuel-air mixture. In the Wankel engine, the piston moves in a circular motion. Like all pistons in an internal combustion engine, it is connected to the crankshaft by a connecting rod and experiences forces from within the engine.

Crankshaft

The crankshaft is a vital piece of the engine, used in rotary engines to convert linear motion from the piston to rotational motion.

It consists of a long metal bar that turns and rotates in a circle and has “cranks” that transfer this motion into linear movement. The pistons push against the rods at the base of the crank to start rotating it, and then the crank continues to spin around its center.

Camshaft

Many people are not aware that rotary engines require a camshaft that is different from those found in traditional piston engines. One of the main differences is that the camshaft used in a rotary engine must be able to spin at the same speed as the shaft. Another difference is that rotary engines do not use valves, so the camshaft only needs to open and close ports to control the intake and exhaust flow.

Flywheel

The flywheel in a rotary engine is used to increase torque and to smooth out power output. Rotary engines are often seen in small, compact vehicles because they fit well in the engine bay. One downside of this type of engine is that it has trouble producing power at low RPMs, which can make it difficult to drive off the line.

Fuel line

Rotary engines are different from conventional piston engines. A rotary engine has a spinning circular motion that is typically powered by an electric motor. A new fuel line was created to offer more durability for the engine, as it is typically used in off-road vehicles. The fuel line is made of fiber-reinforced polymer, which can withstand high temperatures and pressures.

Oil line

The oil line in a rotary engine is used to carry oil from the oil pan to the engine. It is one of three parts that make up an internal combustion engine, and it is typically located beneath the vehicle’s chassis.

Stationary Bearing

Stationary bearings are used in the rotary engines to isolate the crankshaft from the torsional vibration of the engine. Stationary bearings are typically mounted to the engine’s case, with one bearing on either side of the crankshaft. A common misconception is that stationary bearings are not required if there is no torsional vibration.

Thermal Pellet

Thermal pellets used in rotary engines are made from an aluminum and magnesium mixture. This type of material is capable of burning hotter than the fossil fuels used in traditional engines. The use of thermal pellets allows for a greater compression ratio and boost in engine power and torque. They also allow for a smaller overall engine size, due to the less pressure needed to ignite the pellet.

Oil Ring Spring Set

The oil ring spring set is an important part of a rotary engine. It is responsible for keeping the oil in place on the inside surface of the engine, ensuring that it does not leak out or splash up into the engine. The oil ring spring set consists of two rings that are placed in-between the piston and the liner at the top dead center, keeping them apart.

Rotor Counterweight

The rotor counterweight is a key component in the rotary engine. It is designed to balance out the weight of the rotors to make use of centrifugal force. The counterweight is placed at the end of a shaft away from the intake and exits through an opening in the side of the engine housing. This prevents damage to the rotor during operation.

Front Housing

The front housing of the rotary engine is located in the front of the engine and is used to bolt down the engine block. The front housing has 4 bolts that go through it, which are bolted to the engine blocks. It also has an oil pump connection on it, which can be used to supply lubrication when needed. The front housing is made of cast iron.

20B Front Eccentric Nut

The 20B front eccentric nut is a rotary engine mounting component. This eccentric nut is located in the center of the engine near the crankshaft and connects the cylinder head to the engine block. The 20B front eccentric nut can be used on Mazda RX-7’s with model years from 1979-1987 and 1990-1991. This component cannot be found on any other Mazda RX models.

Rotor Gasket Set

Rotor Gasket Set is a type of gasket that is found in a Rotary engine that is used to seal the gap between the inner and outer rotor housings. This set is made up of a front cover, rear cover, exhaust chamber, and collector ring.

FAQs

Does Mazda sell rotary parts?

No, Mazda does not sell parts for the rotary engine, but they do provide a list of certified Mazda dealerships in a different area.

Is Mazda making rotary again?

Not yet, but hopefully, they going to start in 2022. Mazda has not made any official announcements about the rotary engine.

How long do Mazda rotary engines last?

Mazda rotary engines are known for their reliability, but the answer to this question is not straightforward because there are so many different factors that can affect how long an engine lasts.

Why is the rotary engine bad?

The rotary engine is not bad. It’s just not the most efficient engine for most applications. The rotary engine is most often found in sports cars because it has a very high power-to-weight ratio, which gives the car excellent acceleration and top speed.

Conclusion:

Mazda Rotary Parts is constructed in Japan. They are one of the top suppliers in the world when it comes to rotary parts. It is because Mazda has deep roots in motorsports and tuning. Their motorsports history makes them experts when it comes to building high-performance engines, which can be seen when looking at their Skyactiv vehicle lineup.

The Mazda Company was founded in 1920 by Jujiro Matsuda. He had a vision of building the finest vehicles in the world, and their automotive history has been quite successful. They have been the leading manufacturer of high-end sports cars and luxury sedans.